Quotations of designer:

Each piano is the work with infinite pains and crystallization of piano-maker; each piano embodies artistic conception of piano-maker, embodies the personal temperament of piano-maker, is attached with the soul of piano-maker and is the incarnation of piano-maker; each piano, has its own life and character.

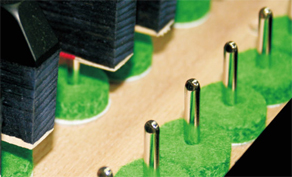

Keyboard and black keys are respectively made of solid wood and ebony

>>Comfortable touch, beautiful and natural; through the built-in weight adjustment, the playing dynamic and static load force may be adjusted. At the same time it has a good sweat-absorbent effect to prevent finger slip and enhance playing feel.

Pressing-type locker

>>Delicate and novel structure makes it easy to operate and to protect the hands from injury.

Keyboard carpet

>>Imported HAINSWORTH carpet from the UK is adopted.

Footboard system

>>Wooden footboard structure in pure European style is adopted.Cast aluminum alloy plate

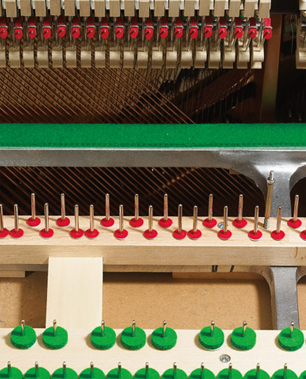

Anti-deformation plate is applied and the piano body is made of cast aluminum alloy material to ensure solid and stable structure and further to ensure that the key chassis is free from deformation, which is a major innovation of piano structure design. Plate subplate is mounted at the bottom of plate and cavity is left between keyboard and plate subplate to enhance the resonance effect of piano.Multi-layer reinforcement string board

Thick and veneer-based high-voltage multi-layer string board with its thickness no less than 32mm is adopted to ensure the best torque. The latest European technology and selected high-quality hard maple are adopted to ensure solid gluing and density uniformity. Special high-quality string axis has special thread as patented design. String axis features in rigorous layout to allow rationally expand the axis spacing and to ensure even torque and improve pitch stability.Rectangular-framed iron plates

Rectangular framed steel structure is applied to ensure that solid and stable string layout of sound source, accurate hole location and reasonable layout.Special sound board

Unequal-width sound board can maximize effective vibration area of sound board, in particular, to increase the effective area of the treble area. When strings vibrate, different frequencies resonate with the corresponding areas of the sound board. Based on the accurately calculated different-thickness sound board and the scientific design, the resonant effect of the sound board and the different frequency vibration is exerted to the utmost.Hammer head

Germany imported FFW special blanket is adopted. The whole set of hammer head has its elasticity and hardness distributed uniformly which may effectively enhance the sound quality. It has beautiful appearance of high-grade, and features in good durability and weather resistance. Hard peach core wood is adopted as core wood of hammer head which has good hardness, toughness and internal stress and is the preferred material for high-end core wood of hammer head in the world.

European plug-in weak sound file

Solid and new structure is adopted for convenience of disassembly and featuring in stable and reliable operation and noise isolation.Shell surface

Side arm, keyboard cover, cover and other parts of shell adopt arc-type transition method which ensures pleasing appearance.Parts assembly precision guarantee

The positioning process is used throughout the manufacturing process. The saddle and sound board, sound board and back frame, back frame and iron plate, the back frame and the shell are made by hole positioning technology, which better guarantees precision of piano assembly.Built-in keyboard cover safety descending device

Beautiful and generous appearance and user-friendly design aim to protect the dexterous hands of the player.Special screws and washers

Iron plate adopts gold and silver fastening screws and cylindrical washers to ensure fine processing and elegant and pleasing appearance.Accuracy adjustment of parts

The whole process of the manufacturing adopts digital management. From iron plate milling, the formation of pillow twisting hole and chord axis hole, to t positioning hole on back frame, milling sound frame, ribbing groove and other processes are completed by high-precision CNC machining center, which ensures higher accuracy of piano parts.